- Monday 8:00AM - 5:00PM

- Tuesday 8:00AM - 5:00PM

- Wednesday 8:00AM - 5:00PM

- Thursday 8:00AM - 5:00PM

- Friday 8:00AM - 5:00PM

- Saturday Closed

- Sunday Closed

2025 John Deere 600M

|

|

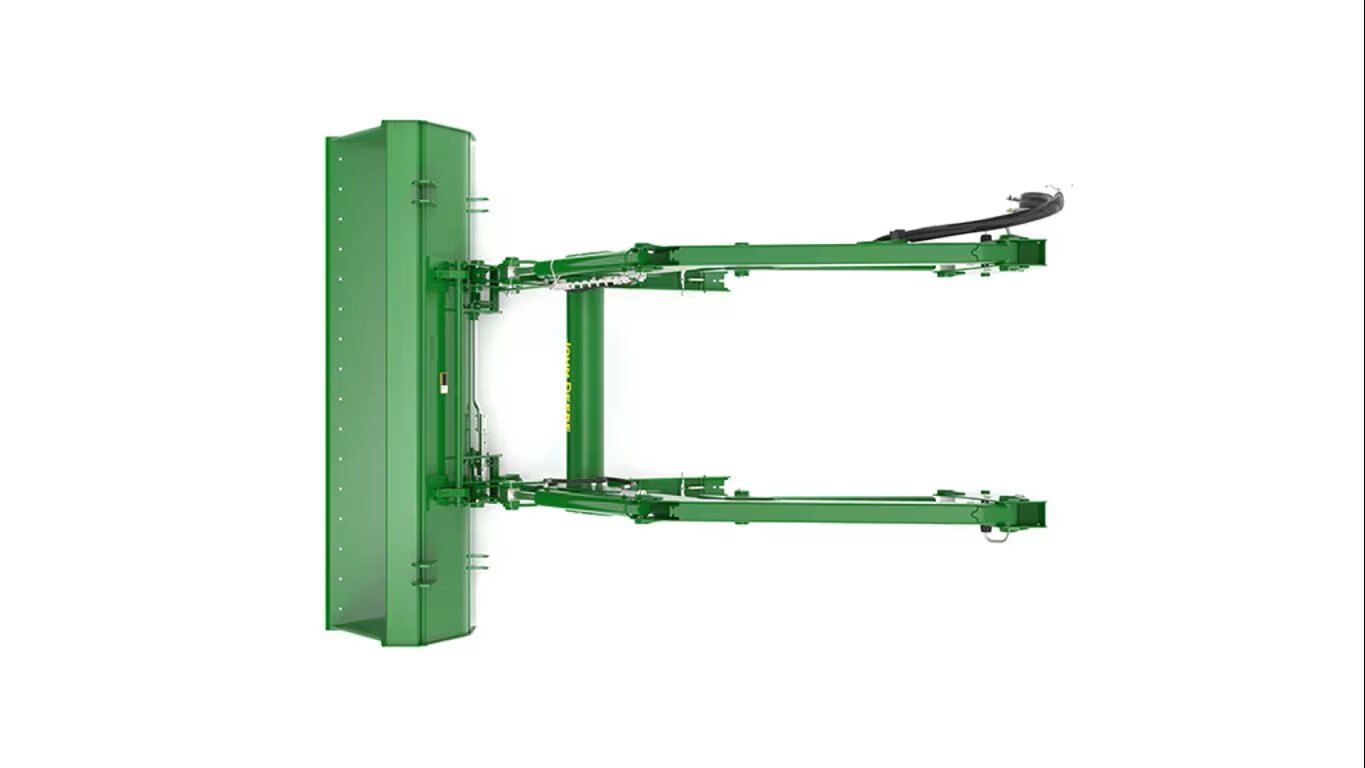

The 540R Loaders comes base equipped with single-point hydraulic connector. This feature saves time and effort when installing and removing the loader.

To disconnect the hydraulic connection between the loader and the tractor, it is necessary to relieve the hydraulic system oil pressure on the tractor. |

|

A hydraulic shut-off valve is included with the M- and H-Series Ag Loaders to ensure the loader does not lower suddenly. For example, this allows the boom to be locked out when someone is required to be located under the loader boom for service work on the tractor. It should not be used for extended periods of time unless an appropriate support stand is also utilized. |

|

Only leave the operator's station once to disconnect the loader

Removing or parking the loader To disconnect the loader, the bucket has to be flat on a stable ground (1). The operator must place the bucket flat on the ground, turn off tractor and release hydraulic pressure from joystick. (2) Exit the operator station and (3) lower the self-adjustable parking stands on both sides of the loader. The self-adjustable parking stands allow the driver to park the loader on irregular terrain and still keep a good position relative to the mounting frame, to attach the loader correctly later on. The parking stands can be set without tools. (4) After lowering the parking stands, the hydraulic couplers on the right-hand side of the loader must be removed and (5) the loader must be unlocked from the tractor mounting frames (both right and left side). |

|

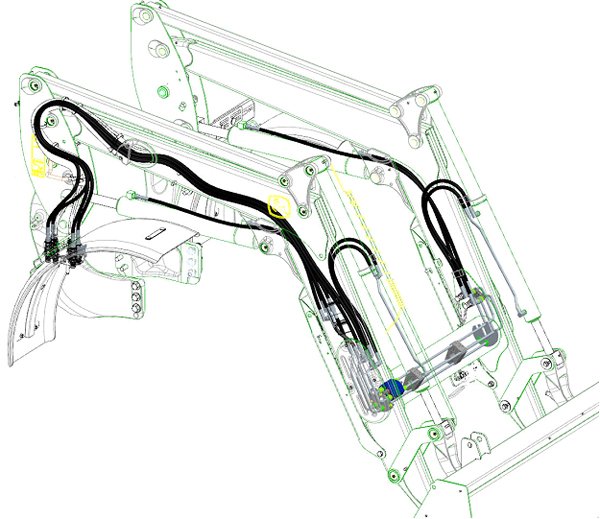

Over time, increased width in tractor hoods have caused issues with available space for running traditional oil lines of a loader along the boom, making them more susceptible to damage.

To improve this situation, the oil lines have been routed through the boom arm and the torque tube, improving line protection and the appearance of the loader.

|

| Model | 6105D/6115D/6130D/6140D |

|---|---|

| Front tire | 14.9R24 |

| Rear tire | 18.4R38 |

| Front axle configuration | MFWD |

| Wheelbase | 2380 mm 93.7 in. |

| Pump capacity | 76 L/min 20.1 gpm |

| Rated pressure | 195 bar 2828 psi |

| Base weight | 1113.2 kg |

|---|---|

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | Materials 1850 mm Materials 73 in. |

| Bucket weight | 281 kg 620 lb |

| Lift capacity at full height | Measured at pivot 1646 kg 3629 lb Measured at 800 mm ahead of pivot 1790 kg 3946 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot 2112 kg 4656 lb Measured at 800 mm ahead of pivot 2021 kg 4456 lb |

| Boom breakout force | Measured at pivot 2583 kgf 5695 lbf Measured at 800 mm ahead of pivot 2259 kgf 4980 lbf |

| Bucket rollback force capacity | At maximum height 1471 kgf 3243 lbf At 59-in. (1500-mm) lift height 2916 kgf 6429 lbf At ground-level line 2986 kgf 6583 lbf |

| Dimensions | Maximum lift height 3830 mm 150.8 in. At full height - bucket level 3636 mm 143.1 in. At full height - bucket dumped 2801 mm 110.3 in. |

| Overall length | 4.9 m 16.1 ft |

| Digging depth | 56 mm 2.2 in. |

| Reach | At maximum height 923 mm 36.3 in. At ground level - bucket level 2519 mm 99.2 in. |

| Bucket angle | Dump angle, degrees -79 degree (angle) Rollback angle, degrees 43 degree (angle) Dump angle, ground -95 degree (angle) |

| Cycle times | Loader raise, seconds 3.9 seconds Loader lower, seconds 2.9 seconds Bucket dump, seconds 2.1 seconds Bucket rollback, seconds 2.1 seconds |

Single-point hydraulic connection saves time

Single-point hydraulic connection saves time

Boom lockout for easy service

Boom lockout for easy service

Loader removal (parking made easy)

Loader removal (parking made easy) Concealed oil lines improve appearance and reduce damage

Concealed oil lines improve appearance and reduce damage