- Monday 8:00AM - 5:00PM

- Tuesday 8:00AM - 5:00PM

- Wednesday 8:00AM - 5:00PM

- Thursday 8:00AM - 5:00PM

- Friday 8:00AM - 5:00PM

- Saturday Closed

- Sunday Closed

2025 John Deere 2100 Minimum Till Ripper

|

|

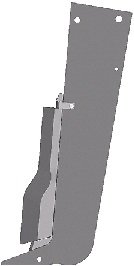

The 19-mm (0.75-in.) straight shear-bolt standard design moves through the soil minimizing soil and residue disturbance at the soil surface.

The 19-mm (0.75-in.) straight standard is base equipment. It is also available as an attachment for field conversion. | |||||||||||||||||||||||||||

|

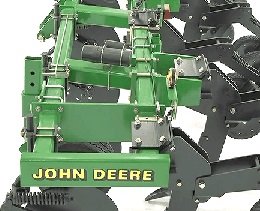

The frame is constructed with a 102-mm x 152-mm x 10-mm (4-in. x 6-in. x 0.375-in.) cross tube on three-, four-, five-, and seven-standard machines and 152-mm x 152-mm x 10-mm (6-in. x 6-in. x 0.375-in.) cross tube on nine-standard models where the hitch-mounting components are welded for maximum strength.

Truss tubes connect the cross tubes and are constructed with 127-mm x 127-mm x 13-mm (5-in. x 5-in. x 0.5-in.) steel tubing.

Welded together into one assembly, the frame is designed to handle the most severe operating conditions.

The mainframe is 4.06-m (160-in.) wide and is the same whether there are five shanks on 762-mm (30-in.) spacings. Frame extensions make this task possible and make configurations easier to adjust | |||||||||||||||||||||||||||

|

A drawn hitch option is available for those who want to use large row-crop tractors or four-wheel drive (4WD) tractors without a 3-point hitch. The drawn hitch is only compatible with seven-standard and nine-standard 762-mm (30-in.) models. The drawn hitch is also available as an attachment for field conversion. The transport wheels are placed in front of the front rank of the mainframe. This allows residue to flow freely and keeps the wheels close to the standards to allow the ripper to follow the ground contour. The wheel modules are mounted to the front, rear, and end frame of the ripper, making it the most stable wheel package in the in-line ripper market. The tires are placed directly in front of the ripper standards so the shanks can remove the tire track to leave as level a profile as possible. There is no need for stabilizer wheels with the drawn hitch. The wheels are located within 762 mm (30 in.) of the outside edge of the machine to provide stability in both field and transport conditions. The nine-standard model has eight-bolt hubs and spindles with beefy 12.5L-15 tires. The seven-standard model uses 11L-15 tires. The large tires provide excellent field flotation and transport stability. A pressure-compensating flow divider is the heart of the depth control system. Temporary adjustments can be made while maintaining the ability to raise and lower evenly. The machine does not need to be fully raised at the end of a pass to keep the cylinders in phase, and cylinder stops are used to set the overall operating depth. NOTE: The drawn hitch attachment is only compatible with serial number 1300 or newer machines.

Three-bar frame models have these strength features | |||||||||||||||||||||||||||

|

Closing wheels can be added to the rear of the 2100 Minimum-Till Ripper with 19-mm (0.75-in.) standards. Closing wheels offer the following benefits:

| |||||||||||||||||||||||||||

|

Cushion coulters cut and size residue and pre-slice the soil to allow a more level soil profile. Cushion coulters are available in two blade choices:

| |||||||||||||||||||||||||||

|

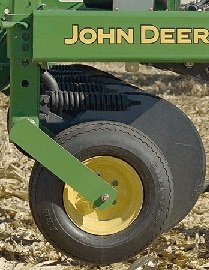

Two adjustable 521-mm x 203-mm (20.5-in. x 8-in.) stabilizer wheels are included in base equipment to ensure straight travel and provide support on three-, four-, five-, and seven-standard sizes. The nine-standard size has four stabilizer wheels.

The stabilizer wheels are designed to stabilize the unit and are not intended to be used as depth gauge wheels. The weight of the unit must be carried on the tractor. Additional stabilizer wheels and tires can be added if field conditions warrant more support | |||||||||||||||||||||||||||

|

Variety of working widths available The 2100 Minimum-Till Ripper is available in working widths from 2.29 m to 6.86 m (7.5 ft to 22.5 ft).

|

| Working width | 2.3 m 7.5 ft 2.7 m 9 ft 3.05 m 10 ft 3.8 m 12.5 ft 4.6 m 15 ft 5.3 m 17.5 ft 6.8 m 22.5 ft |

|---|---|

| Transport width | 3.05 m 10 ft 4.1 m 13.5 ft 5 m 16.5 ft 6.7 m 22 ft 4.7 m 15.5 ft |

| Operating depth | Maximum 40.6 cm 16 in. |

| Miles per hour | 6.4-8 km/h 4-5 mph |

| Horsepower per standard | 22.3-29.8 kW 30-40 hp Depending on soil type, moisture, and depth of operation NOTE: Maximum compatible tractor engine - 231.2 kW 310 hp |

| Spacings | 76.2 cm 30 in. 91.4 cm 36 in. |

| Standard spacings | Inches 38.1 cm 15 in. |

| Type | In-line ripper |

|---|---|

| Option 1 | Standard: 3, spacing: 76.2 cm 30 in. |

| Option 2 | Standard: 3, spacing: 91.4 cm 36 in. |

| Option 3 | Standard: 4, spacing: 76.2 cm 30 in. |

| Option 4 | Standard: 5, spacing: 76.2 cm 30 in. |

| Option 5 | Standard: 5, spacing: 91.4 cm 36 in. |

| Option 6 | Standard: 7, spacing: 76.2 cm 30 in. |

| Option 7 | Standard: 9, spacing: 76.2 cm 30 in. Rigid |

| Option 8 | Standard: 9, spacing: 76.2 cm 30 in. Folding |

| Option 1 | 2.3 m 7.5 ft |

|---|---|

| Option 2 | 2.7 m 9 ft |

| Option 3 | 3.05 m 10 ft |

| Option 4 | 3.8 m 12.5 ft |

| Option 5 | 4.6 m 15 ft |

| Option 6 | 5.3 m 17.5 ft |

| Option 7 | 6.8 m 22.5 ft |

| Option 8 | 6.8 m 22.5 ft |

| Option 1 | 3.05 m 10 ft |

|---|---|

| Option 2 | 3.05 m 10 ft |

| Option 3 | 3.05 m 10 ft |

| Option 4 | 4.1 m 13.5 ft |

| Option 5 | 4.1 m 13.5 ft |

| Option 6 | 5 m 16.5 ft |

| Option 7 | 6.7 m 22 ft |

| Option 8 | 4.7 m 15.5 ft |

| Size | 102x152x0.9.5 mm 4x6x0.375 in. 9 standard: 152x152x9.5 mm 6x6x0.35 in. |

|---|---|

| Maximum underframe clearance | 89 cm 35 in. |

| Inches | 27.9 cm 11 in. |

|---|

| Horsepower per standard | 22.3-29.8 kW 30-40 hp Depending on soil type, moisture, and depth of operation NOTE: Maximum compatible tractor engine - 231.2 kW 310 hp |

|---|

| Option 1 | 3-point hitch for integral |

|---|---|

| Option 2 | Single point for pull-type |

| Option 1 | Pull type: 1 SCV (lift) at 17,237 kPa 2500 psi for optimum raise times |

|---|---|

| Option 2 | Low transport: 1 SCV (fold) at 17,237 kPa 2,500 psi for optimum raise times |

| Options | Integral, or 7- or 9-standard pull type |

|---|---|

| Three-point hitch requirements | Category 2, Category 3 and 3N (with Quik-Coupler) |

| Pull-type description | Level Lift |

| Options | Standard: 19 mm (0.75 in.), min-till point: 178 mm (7 in.), low-disturbance: 254 mm (10 in.), ultra-low-disturbance: 63 mm (2.5 in.) Standard: 31.75 mm (1.25 in.), Regular: 57 mm (2.25 in.), Capped: 57 mm (2.25 in.), Double-capped: 57 mm (2.25 in.) LaserRip points: 70 mm (2.75 in.), 127 mm (5 in.), and 178 mm (7 in.) |

|---|

| Type | Spring cushion coulters |

|---|---|

| Pounds of force | Normal working load: 272.2 kg 600 lb Deflection of: 10.2 cm 4 in. Maximum trip load: 362.9 kg 800 lb Deflection of: 20.3 cm 8 in. |

| Blades | Straight or rippled: 559x4.5 mm 22x0.177 in. |

| Type | Stabilizer wheels |

|---|---|

| Wheels | 52.1x20.3 cm 20.5x8 in. |

| Tires | 10 PR |

| Description | 12.5L-15 tires for 9-standard pull-type; 11L-15 tires for 7-standard, pull-type; 9-standard has 8-bolt hubs and spindles |

|---|---|

| Additional feature | Replaceable wear shin |

| Option 1 | Set back brackets |

| Name | Link |

| View Product Brochure | Download |

19-mm (0.75-in.) straight shear-bolt standard minimizes soil and residue disturbance at the surface

19-mm (0.75-in.) straight shear-bolt standard minimizes soil and residue disturbance at the surface Heavy-duty frame handles tough operating conditions

Heavy-duty frame handles tough operating conditions 2100 drawn hitch option available for seven- and nine-standard

2100 drawn hitch option available for seven- and nine-standard Closing wheel available to minimize surface disturbance

Closing wheel available to minimize surface disturbance Spring-cushion coulters enable more level soil profile

Spring-cushion coulters enable more level soil profile Stabilizer wheels ensure straight travel and provide support

Stabilizer wheels ensure straight travel and provide support